The First Factory in The Space!

A manufacturing facility in Space

Table of Contents (Show / Hide)

SpaceX is teaming up with Varda Space Industries to build the first-ever manufacturing facility in Space. There is no doubt that SpaceX is currently dominating the private space industry. Given the recent commercial success of their projects like the Falcon 9 rocket and the Dragon capsule, SpaceX is really growing as a company and bringing new innovative ideas to the space industry. SpaceX already has so much in the pipeline, like the development of the Starship, the spacecraft that will be taking Humans to Mars in the future. And the development of Star link, the world’s first-ever satellite constellation-based internet provider. SpaceX just recently announced they will be extending support for Star Link in more countries like India. So, let’s dive deep into today’s topic, How SpaceX plans to make a Factory in Space with Varda Space Industries.

Varda Space Industries is central to the plan of making a manufacturing facility in Space to take advantage of microgravity. The company was founded in 2020, and its aim is to make it the first-ever space factory. And when they say a factory, they just don’t mean a small-scale commercial laboratory like the one on the International Space Station. Which NASA and Russia routinely use to make small volumes of materials that can only be made in microgravity for paying customers. And then ship these products back to earth with resupply capsules carrying astronauts and supplies. No, Varda wants to do something exclusive. Varda instead plans to take this concept to a large scale. They want to create an all-in-one and one-stop solution for making different products in microgravity.

Varda’s space factory will not only be able to produce large volumes of material but also actually have to capacity to make larger objects. Orbital manufacturing is not exactly a totally new practice. Like previously mentioned, NASA already does it at some capacity on the International Space Station. And other companies like Made in Space have also been doing this but on a much smaller scale. What Varda wants to do with their factory is basically expand what NASA has done with International Space Station. Currently when NASA has to manufacture an exotic material or conduct an experiment on the International Space Station. They have to launch mini experiment kits and mini-factories with their resupply capsules to the space station. On the International Space Station, the ISS crew has to maintain and troubleshoot this equipment by themselves. This is easier said than done.

But the model of having a present human crew to intervene if anything goes wrong is what attracted Varda. Varda wants to do the same exact thing with their own satellites. Where the sole purpose would be to manufacture the material in microgravity. And when the product is ready, it can be sent back to earth in tiny reentry capsules. According to Varda, these capsules would be able to carry a payload of 100Kg or about 220 pounds back to earth. The aim is for each spacecraft mini factory to spend approximately three months in orbit. The reentry module will bring back around 40-60 kilograms of manufactured materials to earth. SpaceX will be helping Varda get started by helping them launch their first spacecraft onboard a Falcon 9 rocket.

Varda was also working with another famous rocket company called Rocket Labs. Rocket labs is known for their smaller scale rockets to provide cheaper orbital launch services for customers that have smaller payloads to deliver. Varda plans to launch its custom-built space factory on a SpaceX Falcon 9 rocket as part of the SpaceX rideshare program in the first quarter of 2023. SpaceX rideshare program allows customers to carpool their payloads with larger payloads of other customers. Essentially making it cheaper for smaller companies to launch their payloads. The mini-factory satellite is being made in collaboration with Rocket Lab.

Varda purchased Rocket Labs Photon satellite buses. These are basically ready-made off-the-shelf satellites that can be re-purposed for almost any application. Photon can be used to make things like space telescopes, weather monitoring satellites, and even internet service provider satellites. The Photon satellite bus comes with things like solar panels, batteries, avionics, propellant, and optional propulsion upgrades, so companies buying this solution don’t have to worry about designing and making their own satellites. They can just worry about their payload while Rocket Labs handles all the satellite stuff. This is a pretty good sign that the space industry is now maturing where a single company doesn’t have to do everything from scratch and basically re-invent the wheel; rather, they can just focus on their thing and use the services of other companies that are experts in their things.

We will see more companies like these in the future where supply chains are more mature for the space industry. Initially, some people thought that Varda might have a problem collaborating with SpaceX since Varda already works with Rocket Labs, and Rocket Labs also offers launch services. But it turns out that Rocket Lab has no clause preventing Photon customers from launching their procured satellite buses on rockets not built by Rocket Lab. While there are some benefits to using dedicated small satellite launchers like Rocket Lab’s Electron Launcher. It always comes at a price premium, which not every company can pay.

Rocket Labs Electron launch can carry a payload of 200 KG or 440 pounds to a sun-synchronous orbit for a price of $ 7.5 million. It is still more expensive for Varda as compared to carpooling on a Falcon 9 rocket, which will only cost them about $ 1 million. It is important to note that the $ 1 million price is for carpooling the payload with payload from another client. A single Falcon 9 launch can cost upwards of $ 57 million. So, rocket lab is still cheaper if you need your own dedicated launch and your mission doesn’t work if you carpool with other payloads.

Why do we need factories in Space? So now that we know about Varda’s plan to make a space factory, some of the more curious among you might be wondering why we need a Space Factory in the first place? Well, there are benefits to making stuff in microgravity. Especially for making novel and exotic materials. These can be things like bio-printed organs or specialized semiconductors, which would be better made in low gravity environments According to Varda’s own website, some of the Space manufactured products they plan to make are things like fiber optic cables, pharmaceuticals, and semiconductors.

That can include things like ZBLAN based fiber optics, as these would be better made in microgravity environments. Human Organs can also be made in microgravity. These can be made with tissue that is printed with bio-inks made of gel and human stem cells. It would not be possible to make these on earth since they would collapse under their own weight during printing. There are even talks of making exotic metal alloys in microgravity because other elements can mix more evenly with the metals. Varda’s whole business plan depends on whether or not they will find customers willing to pay the premium price for making exotic materials in microgravity.

What do we know about Varda Space Industries? So, what do we know about the company Varda Space Industries? The company itself is very young. It was founded just last year by Will Bruey, Delian Asparouhov, and Daniel Marshall. Will Bruey previously worked at SpaceX, and Asparouhov and Marshall are associated with the Founders Fund of Peter Thiel. The Founder’s Fund was one of the early investors in SpaceX. So, it is sufficient to say everyone involved in this venture has experience working in the Space Industry. The company is based in Torrance, California. In just under a year has managed to raise about $ 52 million in Series A funding. Which is impressive for such a young company.

The founders are aware of what NASA has been able to do on the ISS and are using it as inspiration. Varda founder Asparouhov in an interview, said “The ISS has done a wide variety of materials. We’re not doing new science.” According to Asparouhov, the reach challenge is not the manufacturing technology but rather the development of a re-entry capsule that is supposed to bring back manufactured material to earth. According to him, the company would most likely be singing their first customer within the next 6 months. This is when we can expect to hear more from the company about their future plans.

URL :

News ID : 2158

NASA Just Confirmed: All Life Elements Found on Saturn's Moon Enceladus

NASA Just Confirmed: All Life Elements Found on Saturn's Moon Enceladus

Astronomers Discovered the largest Explosion in Space and Now There is a Problem!

Astronomers Discovered the largest Explosion in Space and Now There is a Problem!

Russia launches its first all-weather satellite

Russia launches its first all-weather satellite

Breaking cryptographic Algorithms with the Help of the Paradox of Birth

Breaking cryptographic Algorithms with the Help of the Paradox of Birth

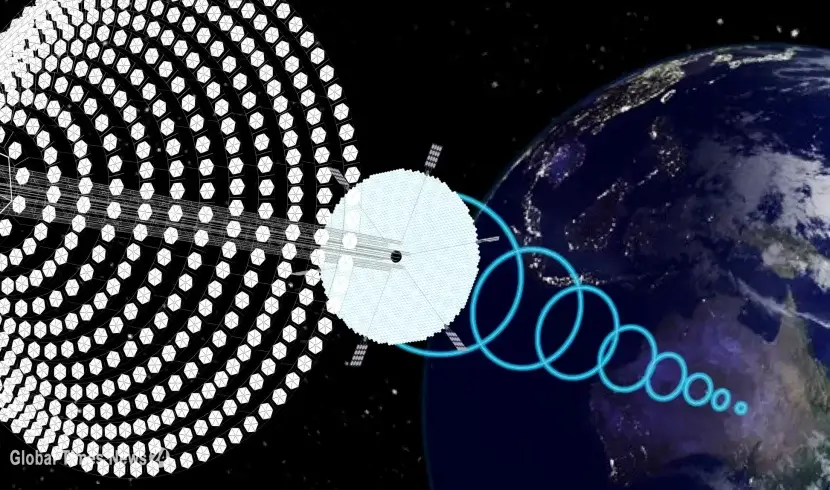

Solar power station in space to beam electricity to Earth

Solar power station in space to beam electricity to Earth

How Japan broke the Internet speed record!

How Japan broke the Internet speed record!

“Oppenheimer”, The Right Movie at The Right Time

“Oppenheimer”, The Right Movie at The Right Time

Major sports events of 2022

Major sports events of 2022

How the FAA went to war against 5G

How the FAA went to war against 5G

The Biden administration is enabling India’s human rights abuses

The Biden administration is enabling India’s human rights abuses